This is a TWO WEEK SPECIAL that is open to all our customers. For every purchase order (PO) we receive between June 15 to July 2, the buyer will receive a half pound bag of our world famous Almond Roca. …

Continue reading

Tag Archives: Aluminum Alloys

Diecasting Airplane Parts

Die Castings used for many Aircraft Parts. Demand for diecast airplane parts is increasing in the aircraft industry. Airplanes need lightweight materials for mobility. Moreover, planes require durability and resistance to several stresses while flying. Among metals, aluminum is used to serve as frames or skeletons of the aircraft.

In the aircraft industry, the strength of aluminum is significantly increased by high pressure die casting. Aluminum die castings used for airplane parts are strong against torsion and expansion stresses. These are important considerations since a flying aircraft is subjected to several forces.

In the machining process, there is always an associated imperfection called die casting porosity. This is the amount of gas that combines with the solidifying metal, as it cools in the mold. Porosity is characterized by the size and number of air bubbles inside the finished product. There are three levels of porosity. The second and third levels are unacceptable when it comes to machining airplane parts. This is to guarantee safety of the passengers.

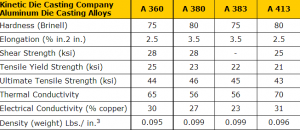

Die castings used for airplane parts are usually made of different aluminum alloys. The two most common die casting alloys for aircraft parts are A380 and A413. For example, Al 7075 is commonly used for making frames because of its toughness.

Permalink: https://www.kineticdiecasting.com/kdc/diecasting-airplane-parts/

To get a price for aluminum die casting parts or die casting tooling, call toll free 800-524-8083 and ask for sales. Or email us at sales@kineticdc.com for a fast response on a price quote.

Kinetic Die Casting manufactures custom metal parts to their customer. If you would like more information about Kinetic Die Casting, please visit our website:Kinetic Die Casting Company

Recycling Aluminum Die Castings

Die casting Parts are completely recyclable. Die Casting Parts have a Planet-Saving Value. These days, many manufacturers are turning to aluminum.

aluminum die casting alloys

Aluminum is a better material to provide their businesses with excellent products that can boost sales. Die casting aluminum is more than just an aluminum production means; it is considered both as an art and a craft.

Unlike plastic, aluminum alloys are completely recyclable. Aluminum is strong and does not deteriorate over time.

Permalink: https://www.kineticdiecasting.com/kdc/recycling-aluminum-die-castings/

The aluminum die casting alloys used in the aluminum die casting process offer designers that are concerned with post-consumer recyclable a highly favorable material option by way of the die cast parts’ reuse feature. Die cast aluminum parts these days, as well as the entire die casting process itself, give product engineers the chance to create and develop aluminum designs that can save the environment. Thus, components in the die casting process are now made to maintain their integrity and quality through disassembly and the consequent tasks of repair, manufacturing, and reassembly – major options that were not available or possible in past years.

What does all this mean? It means that once the lives of die casting aluminum parts end, they are armed with the potential to return to usefulness by becoming part of some other industrial application, and an Kinetic Die Casting Company an aluminum die casting company can indeed help save the planet.

Kinetic Die Casting manufactures products like aluminum hardware, and aluminum boxes. If you would like more information on Kinetic Die Casting, please visit our website:Kinetic Die Casting Company

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Die Casting Aluminum Box Enclosures

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Casting Process

Casting is the process of molding metals into different shapes and sizes to create metal parts. One of the oldest casting methods is gravity casting. Gravity casting uses gravity to make sure that all the parts of the mold is filled by the melted metal like aluminum or zinc. A gating system is produced to ensure a good flow of liquid metal. Basically, all you will need is a gating system a good two piece mold and the melted aluminum. After the liquid aluminum is poured into the mold, it will be left to cool. Even with this simple process, complicated pipe designs may be possible by casting pipes into the mold. However, because you will primarily rely on gravity, it is not ensured that the metal will seep into all the parts of the mold. An inferior plate may be produced. Gravity casting can produce as many as 100 parts in a day.

On the other hand, die casting will surely produce an accurate model of the planned metal fixture. This is because it uses high pressure to pump the melted aluminum into the cold chamber mold. Also, the high pressure ensures the smooth and shiny surface of aluminum parts. Die casting can make 500 to thousands of parts in a day.

To get a price for aluminum die casting parts or die casting tooling, call toll free 800-524-8083 and ask for sales. Or email us at sales@kineticdc.com for a fast response on a price quote.

Kinetic Die Casting is located in North Hollywood,California. KDC specializes in manufacturing zinc and aluminum alloy casting parts. If you would like a quote, please visit our website:Kinetic Die Casting Company

Permalink: https://www.kineticdiecasting.com/kdc/casting-process/

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Zinc Miniature Parts From Kinetic Die Casting Company

Die Casting, Zinc Miniature parts. Aluminum die cast Parts created by Kinetic Die Casting Company could be stronger than steel. Kinetic Die Casting is a die cast part manufacturer of better quality Aluminum die cast parts. Kinetic Die Casting has Low Quantity Die casting Production or High Quantity Die casting Part Production.

High pressure Die casting is a procedure we utilize to create aluminum die cast parts. We poured molten aluminum alloy under pressure into die cast tooling to make aluminum parts. Die casting is an tremendously modest aluminum part assembling procedure.

Die casting procedure uses die cast tooling where molten metal is poured at high pressure. The cast part is taken out of the machine to be cooled before being shipped to the customer. Die casting is great for people who want miniature die cast parts.

Die casting was originally fashioned in the early 1800s. It was originally use for the printing business, yet not long after in assisting in the expansion of shopper things. It essentially made parts reasonable in high volumes. There are essentially two distinct sorts of Die cast machines – hot chamber die casting machine and cold chamber die casting machine. Whether the chamber uses as a part of the process of Die casting is hot or cool hinges on the sort of metal used.

This is the blog on the Kinetic Die Casting Company web site. We also produce Die Casting Tooling. Look at this website page for more details: www.kineticdiecasting.com/tooling_die_casting.html. Contact Kinetic Die Casting Company at sales@kineticdc.com

Do you know someone that can use our services? Call us and let us know 818-982-9200. www.kineticdc.com #diecasting #kineticdc #manufacturing @kineticdc #zinc #zincdiecasting

Kineticdc makes:

Aircraft Die Castings

Aluminum Heat Sink Die Castings

Automotive Die Casting Parts

Die Casting Bracket Parts

Light Fixture Die Casting Parts

Enclosure Box Die Castings

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Die Casting Golf Parts

KDC Popular Roof Protection Concrete Tilemolds

The most popular roof protection is concrete roof tiles. Concrete Roof Tiles have become easier to get because of the technological advancements made by manufacturers that create concrete roof tiles for consumers. For over a hundred years, concrete roof tiles have been considered one of the best options. Today, concrete roof tiles are a smart alternative to clay roof tiles and asphalt roofing. In fact, there are multiple designs and colors that you can choose from. Therefore, because of technology concrete roof tiles have become more and more popular.

Concrete roof tiles are oftentimes more beautiful and cheaper than other roofing materials. Here are some of the concrete roofing tile benefits:

Long Lasting

Since your roof tiles have a concrete base, it is guaranteed to last for a lifetime. Historically, concrete tiles have lasted for over forty to fifty years.

Artistic:

As stated above, concrete roof tiles have different colors and designs to choose from. You can even copy the look of clay, slate and wood roofs using concrete roof tiles.

Low Maintenance:

Since you rarely need to replace concrete roofing tiles, the maintenance is very low. Generally you would only need to replace the affected tiles rather than the whole roof. This effectively cuts down the cost of upkeep to your roof.

Fire Resistant:

Did you know that concrete roofing tiles are fire resistant? They can withstand extreme heat and fire.

Do you need fast delivery for die casting parts?

Do you need prices for die casting parts?

Call us and let us know 818-982-9200.

Kinetic Die Casting Company 6918 Beck Avenue North Hollywood California 91605

www.kineticdc.com #diecasting #kineticdc #manufacturing @kineticdc #tilemolds

Kineticdc makes:

Automotive Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html