Caterpillar Inc. said March 11 it is considering the construction of a new hydraulic excavator plant in the United States that could result in the transfer of some production from Japan. The new facility would manufacturer two excavator models currently …

Continue reading

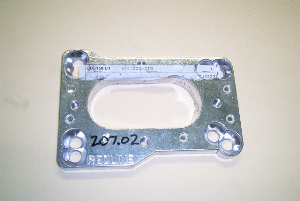

Tag Archives: Zinc Die Casting

Kinetic Die Casting Company on Facebook

![]() Today, we are reminding everyone that Kinetic Die Casting Company is on Facebook Take the time to go to our Facebook page and “Like Us” Our Facebook Page is updated every week with offers to get Homemade Almond Roca and other items pleasing to most people. We post pictures of die casting parts and we post links to web sites that we believe will benefit our followers.

Today, we are reminding everyone that Kinetic Die Casting Company is on Facebook Take the time to go to our Facebook page and “Like Us” Our Facebook Page is updated every week with offers to get Homemade Almond Roca and other items pleasing to most people. We post pictures of die casting parts and we post links to web sites that we believe will benefit our followers.

You will know you are on our page http://www.facebook.com/Kineticdc when you see our motto in the header “The Parts We Make Today, We Ship Today”. Go to our page and click the like button and give us a 5 star rating (*****).

As of today, (May 20, 2015) we have 476 Facebook Page likes. Like the page and we will be happy to like your page in return. If you have something relevant to say, make a comment. As always, we will be happy to supply your manufacturing company with die casting parts produced quickly and at great quality.

Thank you for reading our Kinetic Die Casting Company Blog

Kinetic Die Casting Company (www.kineticdc.com)

6918 Beck Avenue

North Hollywood, CA 91605

818-982-9200

sales@kineticdc.com

Aluminum die casting parts, zinc die casting parts and die casting tooling for all manufacturing industries including automotive parts, lighting parts, military parts, aerospace parts, and many more.

#kineticdc #manufacturing #diecasting #facebook #diecastingcompany

Sad News Joyner’s Die Casting Company – CLOSING

On Monday, I heard about Joyners Die Casting Company is CLOSING. There will be an equipment auction on December 11, 2014 10:00 am CDT for the Joyner die casting equipment. This is very sad news indeed. Another USA die casting manufacturing company closure. This is a continuation of a long sad trend of US Manufacturing companies that struggle and can not stay in business due to EPA issues, employee issues, legal issues and struggles for quality and profit. All this information is available to anyone searching online. Now there is a loss of $10,000,000 in our United States manufacturing capacity. The ones who hurt the worst are the additional 100 Minnesota manufacturing employees who are unemployed and on the street just in time for Christmas.

-

Joyner’s Die Casting & Plating Inc.

7801 Xylon Ave N.

Brooklyn Park, Minnesota 55445

763.425.2104

(Just outside Minneapolis, Minnesota.)

Here is a little information from their website (http://www.joyners.com):

Zinc Die Casting Products Joyner’s Die Casting and Plating Inc. is a Custom Worldwide Manufacturer of Zinc Die Casting Products. We are a Single Source for All Your Zinc Die Casting Needs! Thin wall zinc die casting, Short and long production runs, Stock replenishing programs (KANBAN), In-house tool capability, Zinc Die casting machines ranging from 100 tons to 600 tons. At Joyner’s Die Casting Company and Plating Inc., we’ve been providing all types of industries with the highest quality zinc die castings with machines ranging from 100 to 600 tons. We have the capacity to produce castings from a fraction of an ounce to eight pounds. And with a wide variety of in-house plated and/or painted finishes, we’re able to deliver your product exactly the way you want it. From complete engineering assistance to our ISO qualified program, to our complete laboratory, allows us to die cast your requirement in Zamac 3.

Joyner’s Plating Services Included: Nickel & Duplex Nickel, Bronze, Brass, Gold (14k & 24k), Clear e-coat, Bronze e-coat, Chrome, Black Chrome.

Joyner’s Die Casting Products included: nameplates, handles, hardware, instrument housings, attachments and parts for musical instruments, metal panels, drawer and cabinet pulls, pulleys and sheaves, impellers, elevator, door, safety and warning signs.

Article Link: https://www.kineticdiecasting.com/kdc/sad-news-joyners-die-casting-company-closing/

—————-

This is the die casting blog for the Kinetic Die Casting Company web site. We produce Aluminum and Zinc Die Casting Parts. We are still doing well in spite of the tremendous pressures for pricing, quality and services improvements.

Look at our website page for more details: www.kineticdiecasting.com/

Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices”

Automotive Parts Made with Zinc Die Castings

Useful Information about Die Casting Zinc Automobile Parts. Manufacturing automobiles normally include die casting zinc automobile parts. An automobile is composed of thousands of parts, countless of which are manufactured from zinc. Zinc may also be joined with other alloys to attain detailed purposes. There are useful reasons why die castings is done for manufacturing cars and other four-wheeled vehicle parts:

• Cars are mass manufactured and need many mechanisms; die casting is a fast yet dependable technique to generate metallic parts for them

• Die casting is multipurpose and has the prospective to make parts in changeable shapes and sizes

• The subsequent goods are sturdy and very long-lasting

• It’s inexpensive to die cast car parts likened to other forms of production

• Die casts are readily recyclable and non-toxic

Zinc is an outstanding choice of alloy for constructing auto parts because it is unbending, hard, small, lightweight, non-sparking, and not corrosive. The bulk of vehicles have zinc parts in them because they perform well and are low-priced to produce. Here are some uses of die casting zinc automobile parts:

• For shielding electronic components

• For enclosing airbags, sensors, telematics, switches, and other sensitive equipment

• For constructing solid items, such as lock barrels, seat belts, etc.

• For ornamental purposes – metal platings, finishes, and designs

Though die casting zinc automobile parts is an acclaimed procedure, the quality shaped still be contingent on what the manufacturer does. When buying auto parts, search for a die caster with a decent track record of creating quality parts that have passed difficult testing.

This is the blog on the Kinetic Die Casting Company web site. We also produce Tooling Molds for Die Castings. Look at this website page for more details: www.kineticdiecasting.com/tooling_die_casting.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” www.kineticdiecasting.com/replyform.html

The Different Alloys Used at Kinetic Die Casting Manufacturing

Die Casting Alloys – The Different Alloys Used in Die Casting Manufacturing. Kinetic Die Casting Company uses different types of metal die casting alloys depending on the needs of our customers.

-

The Die Casting Alloys we use are:

- A360 aluminum die casting alloy

- A380 aluminum die casting alloy

- A383 aluminum die casting alloy

- A413 aluminum die casting alloy

- ZA27 die casting alloy

- #3 zinc die casting alloy

- #5 zinc die casting alloy

A380 is the die casting alloy we use the most. About 80% of our parts are produced in A380. A380 is the least expensive aluminum alloy. It is very versatile for a very nice finish on a die casting part.

A360 aluminum die casting alloy is used when corrosion resistance is required. It is used by many manufacturers whose parts are exposed to salt spray or other corrosive environments.

A413 die casting alloy is another alloy we use to produce a lot of parts. This alloy is used in a lot of thermal conductance applications (heat sinks). It has a very nice surface finish and can be used to cast thinner walls. It has better corrosion resistance than A380.

A383 alloy is less expensive than A413 and also is used when the die casting part wall thicknesses are thinner than normal.

ZA27 die casting alloy is used when greater die casting part strength is needed. This die casting alloy is a marriage between aluminum and zinc.

#3 and #5 zinc die casting alloys are the most common alloys used for zinc die casting. Many of the products that were produced in zinc are now made in aluminum or plastic. Zinc makes up less than 10% of the die casting parts made in America today.

Contact Kinetic Die Casting Company for your die casting part needs. (818-982-9200)

Kinetic Die Casting manufactures zinc and aluminium die casting. If you would like a quote, please visit our website:Die Casting quote