Important Metals. Manufacturing a die cast metal part needs equipment like hot-chamber or cold-chamber machines. These machines have the die or mold in them, as well as the injection component for a high pressure mechanism. This will push the molten …

Continue reading

Tag Archives: auto parts

Zinc Die Casting Auto Parts: Advantages and Applications

Zinc Die Casting Auto Parts: Advantages and Applications

In the realm of automotive manufacturing, zinc die casting has gained significant recognition and popularity due to its numerous advantages and versatile applications. Zinc, as a material, possesses remarkable mechanical properties, making it an ideal choice for the production of auto parts.

One of the main advantages of zinc die casting for auto parts is its exceptional strength and durability. Zinc alloys exhibit high tensile strength and excellent impact resistance, which are crucial qualities for components that undergo frequent stress and heavy loads within the automotive industry. This enables the production of sturdy and long-lasting auto parts that can withstand demanding operating conditions.

Additionally, zinc die casting offers unparalleled dimensional accuracy, making it highly desirable for automakers. The ability to create intricate and precise shapes with tight tolerances ensures a perfect fit and proper functioning of the auto parts. This precision helps reduce assembly time and eliminates the need for further machining operations, ultimately lowering production costs.

Another notable advantage of zinc die casting for auto parts is its high thermal conductivity. This property allows for efficient heat dissipation, making it suitable for components that are exposed to high temperatures or require efficient thermal management. Moreover, zinc exhibits excellent corrosion resistance, enhancing the longevity of the auto parts, even in harsh environmental conditions.

The versatility of zinc die casting is truly remarkable, as it can be utilized in a wide range of automotive applications. Engine components, such as housings, brackets, and cylinder heads, can be efficiently produced using zinc die casting techniques. Other auto parts that benefit from zinc die casting include transmission components, steering mechanisms, suspension parts, and electrical connectors.

Furthermore, zinc die casting offers cost-effective solutions for automotive manufacturers. The rapid production cycle time, combined with reduced material waste, contributes to lower production costs compared to other manufacturing processes. This makes zinc die casting an attractive option for automakers seeking to achieve cost-efficiency without compromising on quality.

In conclusion, zinc die casting has become a preferred choice for producing auto parts due to its exceptional mechanical properties, dimensional accuracy, thermal conductivity, corrosion resistance, and versatile applications. With automotive manufacturers increasingly emphasizing durability, performance, and cost-effectiveness, zinc die casting is expected to continue its prominence in the automotive industry for years to come.

“The Parts We Make Today, We Ship Today”

Kinetic Die Casting Company. Inc.

6918 Beck Avenue, North Hollywood,

California 91605, United States of America

E-mail sales@kineticdc.com

USA Toll Free: (800) 524-8083 Local: (818) 982-9200

To get prices for Die Casting Tooling Molds or Parts:

RFQ Die Casting Tooling Part Prices

Kinetic Die Casting Company makes:

Die Casting Auto Parts in 2023

Die Casting Aluminum Auto Parts is fast and inexpensive. We produce several thousand car parts each year using aluminum die casting. Today we received a purchase order from one our customers to produce over 24,000 aftermarket auto parts. We will cast these auto parts using aluminum die casting, we will die trim the parts and ship them in less than six weeks. https://www.kineticdiecasting.com/kdc/die-casting-auto-parts/

Kinetic Die Casting manufactures aluminum die castings creating aluminum die casting boxes, aluminum handle hardware, and aerospace die casting.

If you would like to get a quote, please visit our website: http://www.kineticdiecasting.com/

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood CA 91605

818-982-9200

“The Parts We Make Today, We Ship Today”

Kinetic Die Casting Company. Inc.

6918 Beck Avenue, North Hollywood,

California 91605, United States of America

E-mail sales@kineticdc.com

USA Toll Free: (800) 524-8083 Local: (818) 982-9200

To get prices for Die Casting Tooling Molds or Parts:

RFQ Die Casting Tooling Part Prices

Kinetic Die Casting Company makes:

What Are Die Casting Parts?

Die Casting Aluminum Heat Sinks

Aluminum Boxes Diecastings

Sponsored Listings:

House in Florida

Aluminum Die Cast Auto Parts in 2021

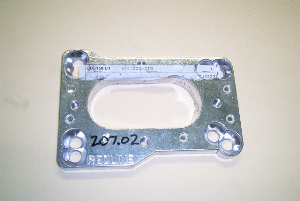

Aluminum Die Cast Auto Parts include radiators, carburetors, gas tanks, valve covers, mirrors, air filter adapters, exhaust systems, body and closure panels, door and trunk handles, auto lamp parts, engine brackets, wheels, master cylinders, ornaments and logos among others.

Aluminum die casting is an incredible way of manufacturing aluminum parts. Die casting is the manufacturing procedure of forcefully inserting molten metal, in this case aluminum, into a steel mold or die and making it solidify to form metal parts. Aluminum is one of the top choices in die casting because it is lightweight, malleable or flexible, and has a high electrical and thermal conductivity. Aluminum has a fatigue or endurance limit that is not yet defined as compared to steel. It surely has very high fatigue strength, perfect for constructing materials that will last for long periods of time.

The Aluminum Die Cast Auto Parts, also called aluminum castings, are exceptionally durable and highly resistant to corrosion. Thus aluminum castings are even utilized in military equipment and automotive parts. In the military, aircraft, missiles, torpedo boats, and armored vehicles such as tanks all contain aluminum castings. Aluminum is also used in lighting fixtures, lawnmowers, heat sinks, medical and dental equipment, roofing tile molds, golfing products, amplifiers, hand tools, typewriter frames, and even kitchen paraphernalia.

Everybody knows what aluminum is since it is used in countless materials and products. Aluminum, known for its low density and ductility as well as its durability and corrosion resistance, has become a wonder metal that can be used in so many ways.

Kinetic Die Casting is a die casting company specializing in aluminum and zinc parts. If you would like to request a quote, please visit our website:Kinetic Die Casting Company

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605, United States of America

E-mail sales@kineticdc.com USA Toll Free: (800) 524-8083 Local: (818) 982-9200

To get prices for Die Casting Tooling Molds or Parts: RFQ Die Casting Part Prices

Kinetic Die Casting Company makes:

Die Casting Quality Standards

Die Casting Porosity

Die Casting Draft Angle

Die Cast Parts Company

Fast Way of Making Aluminum Auto Parts in 2021

Fast Way of Making Aluminum Auto Parts. Aluminum has a very unique property. This metal alloy is very strong and durable. Some even compares its strength to steel. Surprisingly, aluminum is very light for it strength and durability. Because of these characteristics, it has become the metal alloy of choice for many manufacturing companies around the globe. From household appliances such as electric fans and heaters, to consumer electronics such as MP3 players and others, aluminum is used as part of these products. One particular product which loves to use this metal is automobiles. Aluminum Auto Parts are very common and can vary in shapes, sizes and use. Since there is a high demand for these Aluminum Auto Parts, they have to be made fast. This is achieved through die casting.

Die casting is a process of turning the raw material which is aluminum, into the needed part of the company or manufacturer. It is done by first melting the aluminum. The metal is heated with very high temperatures until it liquefies. Once it does, the liquid metal is then injected into casings known as castings. This would give the liquid metal its new shape, in this case Aluminum Auto Parts. Die casting is a fast and reliable process which can provide high quality results.

The process of die casting aluminum is fast and most of all, it is cheap. Not only is it used in making Aluminum Auto Parts, it is used to make a variety of aluminum products as well. This service is offered by many companies everywhere and is a valuable asset to many manufacturers.

Kinetic Die Casting manufactures zinc and aluminium die casting. If you would like a quote, please visit our website:Die Casting quote

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605, United States of America

E-mail sales@kineticdc.com USA Toll Free: (800) 524-8083 Local: (818) 982-9200

To get prices for Die Casting Tooling Molds or Parts: RFQ Die Casting Part Prices

Kinetic Die Casting Company makes:

Die Casting Handle Hardware

Die Casting Alloys

Die Casting Aluminum Alloys

Aluminum Part Castings Company

Die Casting Zinc Automobile Parts 2021

Useful Information about Die Casting Zinc Automobile Parts. Manufacturing automobiles normally include die casting zinc automobile parts. An automobile is composed of thousands of parts, countless of which are manufactured from zinc. Zinc may also be joined with other alloys to attain detailed purposes. There are useful reasons why die castings is done for manufacturing cars and other four-wheeled vehicle parts:

• Cars are mass manufactured and need many mechanisms; die casting is a fast yet dependable technique to generate metallic parts for them

• Die casting is multipurpose and has the prospective to make parts in changeable shapes and sizes

• The subsequent goods are sturdy and very long-lasting

• It’s inexpensive to die cast car parts likened to other forms of production

• Die casts are readily recyclable and non-toxic

Zinc is an outstanding choice of alloy for constructing auto parts because it is unbending, hard, small, lightweight, non-sparking, and not corrosive. The bulk of vehicles have zinc parts in them because they perform well and are low-priced to produce. Here are some uses of die casting zinc automobile parts:

• For shielding electronic components

• For enclosing airbags, sensors, telematics, switches, and other sensitive equipment

• For constructing solid items, such as lock barrels, seat belts, etc.

• For ornamental purposes – metal platings, finishes, and designs

Though die casting zinc automobile parts is an acclaimed procedure, the quality shaped still be contingent on what the manufacturer does. When buying auto parts, search for a die caster with a decent track record of creating quality parts that have passed difficult testing.

This is the blog on the Kinetic Die Casting Company web site. We also produce Tooling Molds for Die Castings. Look at this website page for more details: www.kineticdiecasting.com/tooling_die_casting.html. Contact Kinetic Die Casting Company at 818-982-9200 or email us at sales@kineticdc.com. Use this webpage to request “die casting part prices” https://www.kineticdiecasting.com/replyform.html

Die Casting Auto Parts

Die Casting Car Parts

Manufacturing Die Casting Parts

Aluminum Die Casting Company

Photos Die Casting Car Parts

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

We put the parts in poly bags, pad the parts and boxes.We put the parts in poly bags, pad the parts and boxes. Toll Free: (800) 524-8083 Local: (818) 982-9200 E-mail sales@kineticdc.com

Die Casting Automotive Parts Prices