New Cast Aluminum Golf Products. Golf is a very exciting sport that needs precision, accuracy and strength. If you are a golfer, you would do anything to have these three qualities for better chances of defeating your competitor. But aside …

Continue reading

LJ Die Casting Company

Today, I was driving and looked at an old brown building to my left and saw the name, L. J. Die Casting. I know that LJ Die Casting Company does not have any die casting machines. They sold all of them about 10 years ago. When I had stopped by about 6 years ago the manager at the time said they sold the machines and now import all their aluminum parts from overseas. I was curious today and wanted to stop to see why the building still has LJ Die Casting outside. I walked into the door and saw two workers grinding sand castings. I looked in the next small building and saw more aluminum lighting parts. I saw a lot of light fixture parts. In the next work area I asked a guy who is the manager? He pointed to a small building out back. I walked up to the building and out walks two men. The first man I did not know, it turns out his name is Jesus. He walked around the building to another warehouse in back. The second man I knew to be the general manager of now closed, Alcasto Die Casting Company, his name is Dale Weitzel.

When he looked up at me, Dale got a shocked look on his face.

He asked me “what are you doing here?”

I told him, “I am looking for the manager”. Dale said “he just went around the corner”.

Then Dale turned to lock the door to the office.

I said, “you are not the manager?” He said “no, I am retired”.

I said, “if you are not the manager, why are you locking the door?” He said, “the guy who left told me to lock it”.

He said, “I stopped by here to see if these guys can make a gun lock part I need”.

Then Dale walked quickly toward his truck to leave. I followed and told him, “I would like to meet the manager, what is his name?” Dale said, “Jesus”. Then Dale told me he has not worked since closing Alcastco, about three years. Then Dale drove away quickly.

I walked around the corner in the direction that Dale said Jesus walked. I walked into another warehouse area with more lighting parts made overseas. I was wondering, how do these guys stay in business?

I found Jesus and asked him if he needed parts made by Kinetic Die Casting Company, a local die casting company. He indicated that he is the shipping guy. I need to talk to his manager, Dale Weitzel. When I asked for a card, he gave the business card that said “LJ Die Casting, Serving the Lighting and Lamp Industry, Dale Weitzel, General Manager”

What a strange conversation I had with Dale. Why did he feel he had to be dishonest with me? I am not sure that I will ever understand?

Kinetic Die Casting Company, Inc.

6918 Beck Avenue

North Hollywood, CA 91605

“The Parts We Make Today, We Ship Today”

Die Casting Part Quotes

Aluminum Enclosures

What sensation aluminum has become in the hardware market is no secret. The metal and its derivatives are being widely being used in not only huge companies such as automobiles and aeronautics but also in small scale usage such as boxes and enclosures for mundane activities. Here is guide to the benefiting properties which make aluminum a favorite over its other metal and alloy counterparts, especially when it comes to boxes and enclosures. This article would also successfully hope to throw light on different purpose for which the boxes are being manufactured for.

DURABILITY

As of now, Aluminum is the most durable and its product the most stable, as compared to any other metal and its products if gauged on the scale of practical use. The aluminum boxes and enclosure, whether big or small are highly resistant to corrosive reactions and this one property is largely responsible for aluminum’s long life span.

PROTECTS THE STORED MATERIAL

Also, Aluminum alloy and the derivatives obtained from it have a very low reactivity when they come in contact with air. There may be many elements and metals which are much lighter and durable than aluminum but lose out because they react vigorously when kept in the atmosphere. These highly reactive metals cannot be used to make something for casual use like normal boxes. Aluminum, being low on reactivity protects the stored material inside form reactants and attacks from outside.

LIGHTER AND GOOD TEXTURE

Furthermore, Aluminum is very light as compared to other alloys/metals. This is one reason that huge enclosures which to be transported over long distances are made out of aluminum so that loading and unloading is a much easier task.

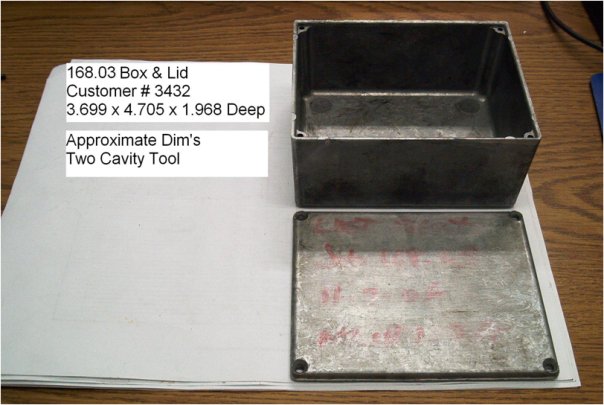

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Boxes. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting every week.

Contact us to get die casting prices http://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

We Honor Competitors Parts Prices on Transfer Tooling

Faster and better Aluminum Die Casting Parts and Zinc Die Casting Parts, No risk to you. Transfer your die casting tooling with a PO and we will match the part prices. You will get great quality parts in 4 weeks or less. Send your die casting tooling, molds and trim dies to Kinetic Die Casting Company with a die casting part (PO) purchase order. We will honor our competitors die casting part prices and ship you great quality die casting parts in less than 4 weeks.

We are still offering a Tooling Transfer special. When another die casting company fails to do a good job. Fails to ship good quality die casting parts. Fails to ship aluminum die castings on time. The manufacturing company customer transfers their die casting tooling to Kinetic Die Casting Company, a better die casting part supplier.

Kinetic Die Casting Company makes that decision easier this week.

1. Send us your die casting tooling and die casting molds

2. A purchase order made to us with your old suppliers prices.

3. We will honor the die casting part price paid to the old die casting part supplier.

4. You will get better die casting parts than you received before.

5. We will ship the die casting parts to you in less than 4 weeks.

Kinetic Die Casting Company 6918 Beck Avenue North Hollywood California 91605 USA

Office Hours: Monday through Thursday 6:00 AM to 4:30 PM (Pacific Time)

818-982-9200 – sales@kineticdc.com – www.kineticdiecasting.com

Die Casting Part Prices

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Parts Today

Kinetic Die Casting Company produces parts for many different industries. Aerospace parts, Military parts, Automotive parts, Speaker parts, Missile parts, Armored Vehicles, Aluminum Boxes, Fire Suppression Housings, and Night Vision Goggle parts.

Look at this video to see some of our die casting parts images:

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, CA 91605

Get a Die Casting Price

818-982-9200 – sales@kineticdc.com

Kineticdc makes:

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts

To get a quote, use this webpage: Die Casting Parts Prices

Military Parts in Two Weeks from Kineticdc

Do you need fast delivery for military die casting parts? Kineticdc shipped aluminum military parts that are 380 aluminum die castings that were machined, impregnated, chemical filmed and we shipped them in less than two weeks from the day we received the purchase order from our customer. We strive for excellence.

Here are the details: Our customer made a commitment to their customer of completed parts in less than two months. Our customer contacted Kinetic Die Casting and offered to pay COD if they could receive parts in less than 4 weeks. We put the mold in our die casting machine and cast the parts that day. We machined the die castings while they were still warm. We dropped them off for impregnation that afternoon and picked them up a few days later. We then chem-filmed the parts and shipped them in less than two weeks.

Know someone that wants to buy die cast parts and can use our die casting services?

Call us and let us know 818-982-9200

Click this link to submit a request for quote form http://www.kineticdiecasting.com/replyform.html

The Parts We Make Today, We Ship Today

Kinetic Die Casting Company 6918 Beck Avenue North Hollywood California 91605

www.kineticdc.com #diecasting #kineticdc #manufacturing @kineticdc

Kineticdc makes:

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Consumer Products Aluminum Parts

Aerospace Die Casting Parts

Military Die Casting Parts