1. Why Should you Use Aluminum Hardware Brackets? The use of aluminum hardware brackets is becoming more and more popular than that of their steel counterparts. Why is that so? Well, basically, the reasons can be unending. From its flexibility …

Continue reading

Tag Archives: Enclosures

B. Bunch Company Closed

Kinetic Die Casting Company first started making aluminum die casting parts for B. Bunch in 2004 when C&D Die Casting Company Closed. B. Bunch Company would buy about 500 aluminum die casting parts a year or every two years. Last year, 2023, I received a call telling me that B. Bunch would be closing. I was again very sad that a great American manufacturing company would be closing. Parts can still be purchased from this website https://kbfolderparts.com/

Die Casting Aluminum Part

Information from their old website: (http://bbunch.com/)

Parts can still be purchased from this website https://kbfolderparts.com/

B Bunch Co., Inc.

9619 N 21st Drive

Phoenix, AZ 85021-1895

USA

phone 602-997-6452

fax 602-997-7266

“B. Bunch Co., Inc. shipped its first fan folding machine on April 21, 1968. Since then, the product line has expanded to more than 60 different machine types including more than 30 styles of Folders, and several different types of Sheeters, Unwinds, Rewinds, Processors as well as specialized accessory printing equipment. More than 7,500 machines have been supplied to forms and label companies, and specialized printing, paper processing plants, and data centers world- wide.”

B. Bunch, as a manufacturing company customer, always paid their invoices for die casting parts timely. B.Bunch gave very good feedback on their production part’s needs and communicated very well with our company, Kinetic Die Casting Company. We will miss the company and the people that worked there.

Kinetic Die Casting Company, Inc.

6918 Beck Avenue, North Hollywood, CA 91605 USA sales@kineticdc.com

Permalink: https://www.kineticdiecasting.com/kdc/b-bunch-company-closed/

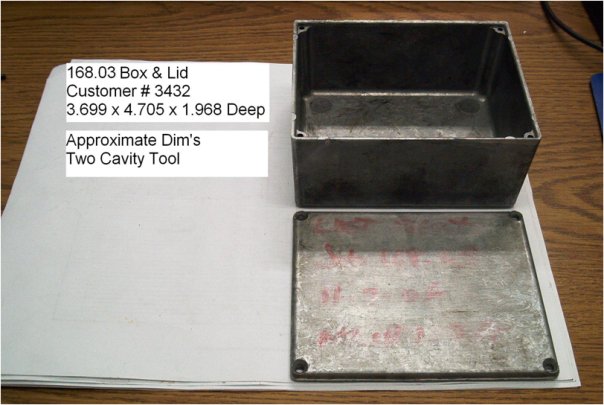

Diecast Enclosures 2019

Die Casting Aluminum Enclosures made by Kinetic Die Casting Company. If you are looking for enclosures which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 25 years old and is currently located in North Hollywood, California.

Die Casting Aluminum Enclosures made by Kinetic Die Casting Company. If you are looking for enclosures which can provide security to the electronic components of your equipment, Kinetic Die Casting makes Die Casting Aluminum Boxes. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company that manufactures the aluminum parts used in the products of Original Equipment Manufacturers or OEM’s. The company is now 25 years old and is currently located in North Hollywood, California.

Kinetic Die Casting Company makes die cast aluminum enclosures through the manufacturing process which requires the use of a die casting machine which will inject molten aluminum into a steel die casting mold tool. This process will produce the aluminum die cast parts which are used by the company in manufacturing their high quality products. Since the enclosures are produced through die casting, the boxes are more durable and stable. These boxes are also competitively priced and can be used for communication devices, motors, electrical junction boxes and elbows, trucks, automobiles, and computer parts. They also produce boxes which are painted, polished, ball burnished, or assembled depending upon the need of the customers. In case the aluminum boxes or parts received by the customers are not right, Kinetic Die Casting Company will replace the product or parts at no additional charge.

Die Casting Aluminum Box Parts

Kinetic Die Casting Company makes aluminum die castings as Die Casting Aluminum Enclosures. As a Die Casting Company, we make these parts every day and ship thousands of these aluminum die casting parts every week.

Contact us to get die casting prices https://www.kineticdiecasting.com/replyform.html.

Kinetic Die Casting Company

6918 Beck Avenue

North Hollywood, California 91605

Sales@kineticdc.com

Aluminum Box Enclosure Uses

Die Casting Aluminum Boxes are used in many ways. How are Die Casting Aluminum Box Enclosures used? These boxes are used for retail product packaging because they can easily get grounded since aluminum can conduct electricity. These are also used as enclosures for parts which should be protected from sudden impact, dust, or moisture. These boxes are also used as a means of blocking away radio waves and frequency which may affect the capacities of the electronic components. It offers protection to the electronic components by providing RF or EMI shielding.

Aside from these uses, a die casting aluminum box enclosure is also utilized as a “grounding plane” or as a common electrical circuit for the electrical machinery inside the box. Die casting aluminum boxes can also be used as storing equipment since they are durable enough to contain materials when one is out on a road trip. These boxes can be manufactured huge so these can be used at the back of pick up trucks. But they can also be crafted in a small size so they can be used in the home as storage for magazine and comic book collections. These can also be used as mailboxes which can survive the harsh weather for a couple of years. Die casting aluminum boxes are also used as large transportation enclosures for both equipment and animals.

Permalink: https://www.kineticdiecasting.com/kdc/aluminum-box-enclosure-uses/ ?

“The Parts We Make Today, We Ship Today”

Kineticdc makes:

Aluminum Heat Sinks

Automotive Die Casting Parts

Airplane Die Casting Parts

Light Fixture Die Casting Parts

Die Casting Aluminum Box Enclosures

Aerospace Die Casting Parts

Military Die Casting Parts

Die Casting Tooling

Kinetic Die Casting Company 6918 Beck Avenue, North Hollywood, California 91605 USA

E-mail sales@kineticdc.com Toll Free: (800) 524-8083 Local: (818) 982-9200 Fax: (818) 982-0877

Draft Angles in Die Castings

Kinetic Die Casting Company discusses “Draft Angle in Die Castings” – “what is draft angle in an aluminum metal box casting?” or “why do I need a draft angle on my aluminum die casting box part?” The mechanical reply is, all aluminum die castings need a draft angle on the walls of die cast box parts perpendicular to the parting plane or parallel to the slide interfaces. Because I have been selling die cast parts for over 20 years, I find easy answers and give simple calculations for my clients. What does that have to do with the usual engineer (any engineer other than in tooling or mechanical) or professional buyer?

Most people do not have the need to worry about how things are made; only what is made, and will it be what is essential. “Have you ever observed on a cupcake the bottom diameter is smaller than the top diameter?” or “Have you noted that a cake pan has sides that slope in toward the middle of the pan?” That would be an extreme case of a draft angle. Aluminum die castings would stick inside the die casting tool, molds, or die casting die if there was not enough draft angle in the tool and part. The usual draft angle for an aluminum die casting part is two degrees per side. The calculation for that is easy if a anyone is acquainted with die casting production part design.

Imagine an enclosure (or Aluminum Box) lying on a counter with the open side up. The aluminum box is 2″ deep inside with the height and width 4″ each way on outside. The walls of the box are 0.10″ in width. Due to the wall’s thickness, a few things are obvious to a part designer regarding this seemingly simple box:

A 2 degree draft angle will alter the dimensions in the following on the interior and exterior and should be regarded if something needs to fit inside the box or outside the box:

If the box was intended for the interior of 4″ x 4″ at the bottom: box:

See our die casting draft webpage: http://www.kineticdiecasting.com/draft.html

Contact Kinetic Die Casting Company at 800-524-8083 for more information

http://www.youtube.com/user/kineticdc

The Many uses of Die Casting Aluminum Boxes

The Many uses of Die Casting Aluminum Boxes. Kinetic Die Casting Company makes many types of aluminum boxes using the die casting process. These “Boxes” are also known as “Chassis” or “Enclosures” and “Housings”.

This aluminum box known as a Guitar Amplifier Chassis, was used in the music industry:

Guitar Amplifier Chassis Die Casting

This is an aluminum die casting part that was developed here at Kinetic Die Casting Company for a company called Damage Control. Damage Control purchased thousands of these aluminum Guitar Amplifier Chassis from us in 100-200 part increments, complete and ready for assembly. The tool to produce this part has three slides and the tool cost them around $20,000 to produce. The part cost is around $3.00 each part.

This die casting part is a military housing:

Military Die Casting Photos

This part is an aluminum die casting that Kinetic Die Casting Company does a radio-graphic inspection then impregnates and then machines the required threads and complete the part with a chemical film prior to painting the part. These parts are purchased in lots of 50-100 parts.

This next item is a lot more common. This is an electrical conduit housing:

Kinetic Die Casting company produced 16,000 parts for this company every week before they were purchased by a much larger company and moved to India.

Evidently, there are several types of aluminum boxes produced as a die casting part. We can help you with your aluminum box product development. Cal us today to review your aluminum box part design.

Kinetic Die Casting manufactures aluminum die castings creating aluminum die casting boxes, aluminum handle hardware, and aerospace die casting. If you would like to get a quote, please visit our website: Kinetic Die Casting Company