|

Aluminum Stronger than steel? |

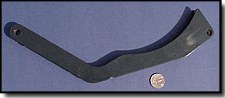

Steel Weldament

Steel Weldament |

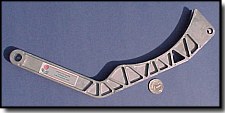

Aluminum = 3x Axial Strength

Aluminum = 3x Axial Strength |

Are aluminum V2-AC 090 die casting parts stronger

and cheaper than steel?

How can an aluminum die cast part be stronger than a steel weldament? Kinetic Die Casting, Inc. makes an aluminum die

casting cam lever part for a lift manufacturer that once was a two pound steel welded unit.

This unit consisted of two steel plates, 1/8" thick, with holes drilled, tapped, and welded to steel spacers with a bushing

at each end, then painted. Occasionally, these units would fail in the field.

Manufacturing costs ran about $7.00 per part in production quantities of 1,000 each week.

Another difficulty is that it took three to four weeks to make the first steel part and only a few 100 could be produced a

week. This hindered increased sales.

Kinetic Die Casting now produces these Ricon V2-AC 090 parts

(Email us (sales@kineticdc.com) in aluminum die casting that weigh only 3/4 pounds; the steel unit weighed

over two pounds. The aluminum die casting parts are stronger (3x greater axial load) and more reliable. There is no need

for paint on the aluminum die casting parts. The Kinetic Die Casting part price of each die casting unit is less than

$3.00 each part.

Kinetic Die Casting can help you develop an aluminum die casting that will reduce weight, increase strength,

and cost you less money.

|